Lawler Manufacturing Company Blast Gates are made of certified aluminum alloy and proudly made in America.

Blast Gates are used to focus a dust collection system ‘s vacuum pressure for maximum dust (or other material) extraction at the desired location. Blast gates are positioned near individual pieces of machinery and operate by being, by default, closed – blocking air flow. When one blast gate is opened, all available suction is focused at that location, maximizing the amount of material collected.

Note that in larger dust collection system installations with more available power, multiple blast gates may be opened at the same time without detriment to collection abilities at individual locations. In fact, some systems are so powerful that at least one blast gate must be open at all times, or the system can collapse itself.

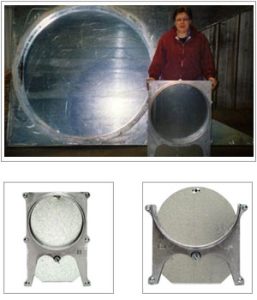

Clean Out Doors. Quick opening hinged cleanouts can be used for easy product sampling while system is in operation or for emergency servicing or unplugging. Available in both bolted and hinged flat construction in opening sizes 4-1/2″ x 9″oval and 9″ x 18″ oval.

Cast aluminum bolted curved cleanout doors are available to fit pipe diameters 6″ – 20″ and hinged curved cleanout doors are available to fit pipe diameters 6″ – 16″.

Standard Blast Gates are fabricated from 10 gauge steel in sizes 4″ – 24″, custom sizes and materials available. 4″ – 20″ manual operated are normally in stock. Offered in manual, pneumatic or electric operated construction with flanged connections.

Blast gates provide a more positive seal than cut-offs and work equally well with positive or negative pressure. Available with square inlets and outlets. Shop drawings are available.

Hot Rolled Steel Blast Gates are used to focus a dust collection system ‘s vacuum pressure for maximum dust (or other material) extraction at the desired location. Blast gates are positioned near individual pieces of machinery and operate by being, by default, closed – blocking air flow. When one blast gate is opened, all available suction is focused at that location, maximizing the amount of material collected.

Note that in larger dust collection system installations with more available power, multiple blast gates may be opened at the same time without detriment to collection abilities at individual locations. In fact, some systems are so powerful that at least one blast gate must be open at all times, or the system can collapse itself.

Pneumatic Blast Gates are fabricated from 10 gauge steel in sizes 4″ – 24″, custom sizes and materials available. 4″ – 20″ manual operated are normally in stock. Offered in manual, pneumatic or electric operated construction with flanged connections.

Blast gates provide a more positive seal than cut-offs and work equally well with positive or negative pressure. Available with square inlets and outlets. Shop drawings are available.

Self Cleaning Blast Gates available from 2″-24″ are the same construction as Full Blastgates except the galvanized steel blade pushes material like green wood, or wood sap through the end of the blastgate casting. This allows the blade to close without jamming on compacted materials.

Skeleton Blast Gates available from 2″-24″ are the same construction as Full Blastgates except the galvanized steel blade pushes material like green wood, or wood sap through the end of the blastgate casting. This allows the blade to close without jamming on compacted materials.

Stainless Steel Blast Gates available from 2″-24″ made from #304 or #316 stainless steel alloy are the same construction as Full Blastgates with a stainless steel body and blade. This allows the blade to close without jamming on compacted materials.